Recommissioning Tanks: What Role Does NDT Play? (Part 2)

By: Eng. Jesus Eduardo Contreras

The oil and gas industry experienced some major challenges in 2020. With the sudden reduction in fuel consumption, there was a substantial global surplus of crude oil. This unique situation has seen storage facilities reach maximum capacity and even crude tankers being used to store unwanted product.

Retired storage facilities are being targeted for reinstatement, and operators are considering tank construction to increase capacity. With increased storage requirements and potential inspection deferrals, there is also an increased requirement to perform in-service tank inspection to assess critical components within the asset.

This article will do a complete NDT techniques revision that can be applied to the recommissioning tanks.

Tank shell plates

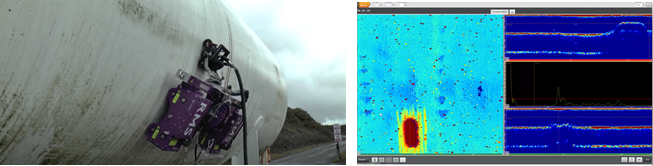

Traditionally, an inspection technician would take three ultrasonic thickness measurements per shell course. The technician would use rope access, scaffolding, or a mobile elevating work platform to access the predetermined locations. This technique can result in misleading results due to the low Probability of Detection (PoD). In addition, providing access for manual inspection is extremely costly and is not productive. Modern tank shell inspection utilizes automated robotic crawlers. The remote-controlled crawlers (Fig. 1) drive up the tank shell collecting thousands of UT thickness measurements, or a more advanced PAUT system collects corrosion mapping data. This modern technique has many advantages, such as a much higher PoD, increased operator safety, reduced inspection costs, and recorded auditable inspection.

Tank Roof Plates

Like the other components of aboveground atmospheric storage tanks, roof plates must be inspected for corrosion and deformation, and cracking in welding joints. Inspection standards state that walking on tank roofs can be hazardous. The condition and thickness of roof plates should be confirmed before access is permitted. Automated remote access UT scanners (Fig. 2) can be utilized to determine the roof plate’s condition without any human access.

Tank Welds

The traditional technology for inspecting welds for non-through-wall defects is Magnetic Particle Inspection / Magnetic Testing (MPI/MT). Inspection authorities now recognize Alternating Current Field Measurement (ACFM) (Fig. 3) and Eddy Current Array (ECA) as an alternative method to MPI/MT. These modern techniques do not require the removal of any coatings and can accurately detect and size a weld crack faster and more cost effective than MPI and without the need for consumable chemicals.

Tank Piping

Piping connected to a storage tank has various vital roles in daily operation, such as product import / export, water drain off, and vapor recovery systems. This piping can be at a low level, high level or even buried underground. Selecting the correct NDT inspection technique is critical to the overall integrity of the storage tank system.

Let see several conditions inspected by different techniques:

- Pipeline and Buried pipe (Guided waves) (Fig 4)

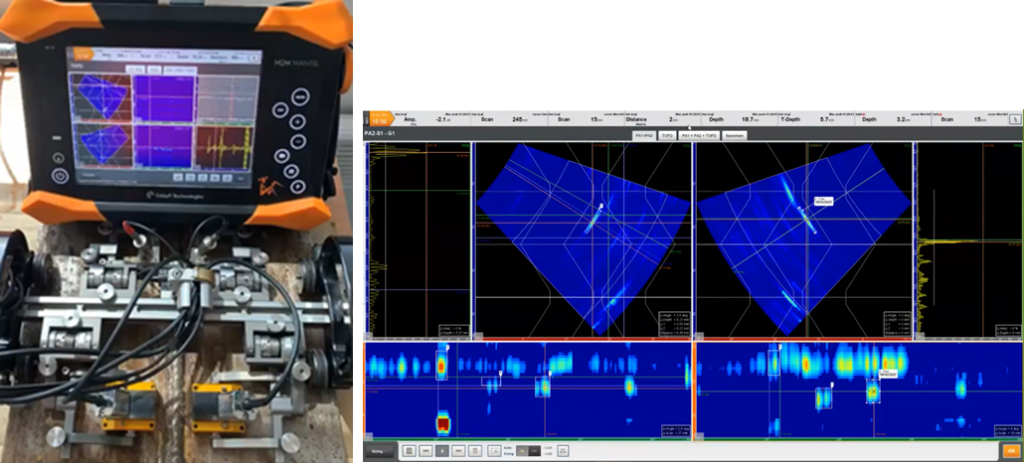

2. Welding inspection and corrosion mapping in pipe: PAUT system with PA and TOFD transducers with a magnetics scanner, in the right side, a typical layout shown S, C and A-Scan (Fig. 5)

3. Corrosion under insulation (CUI) affect insulation pipeline and sphere legs. The PEC and PECA techniques (Fig 6) are the most effective tools to inspect both applications.

You will find more details about the complete set of NDT techniques, do not hesitate to contact with us!