Tank Inspection In-Service Condition: The Acoustic Emission (AE)

By: Eng. Jesus Eduardo Contreras

Petroleum tanks used to store crude oil, aviation fuel, gasoline, diesel and other products above and below ground. Leaking tanks may create significant environmental damage and jeopardize safety. Soil and water contamination can be tremendous and be undetected for years.

Different methods have been developed and applied during the recent decades for non-destructive evaluation of metal and fiber-reinforced plastics (FRP) structures. Among these methods, acoustic emission technology is unique as it not only detects flaws but also is used for on-line, real-time monitoring of structural integrity without interruption of operation, cleaning, or product evacuation.

In-service condition: The Acoustic Emission (AE)

Acoustic Emission (AE) – this technology allows qualitative assessment of the floor condition while the tank is in-service and provides valuable input to an RBI program concerning the floor probability of failure due to corrosion. Valves attached on the tank are also evaluated for leakages, as part of the inspection. Once the tank is opened, quantitative damage assessment for maintenance actions is achieved by other advanced NDT technologies such as Magnetic Flux Leakage (MFL) mapping, Ultrasonics corrosion mapping, and other methods as Pulsed Eddy Current (PEC) or Short-Range Wide Wave (SRGW), in accordance with pertinent codes and standards (API 653 or EEUMA 159).

Let us detail more on the Acoustic Emission.

Principles of the method

Acoustic Emission is the process of detecting the sound produced by the discontinuities of the bottom plate of the storage tank when it has leakage or corrosion. The sensitivity of the method detects noises of discontinuities that are even below 2dB. The temperature ranges at which the tank can be evaluated will depend on the resistance of the sensors attached to the tank walls to perform the test.

Types of tanks where EA is possible: single wall, double wall, fixed roof, floating roof.

Normative

ASTM:

- E 569 – Acoustic Emission Monitoring of Structures During Controlled Stimulation

- E 650 – Guide for Mounting Piezoelectric Acoustic Emission Sensors

- E 750 – Practice for Characterizing Acoustic Emission Instrumentation

API:

- RP 575 – Guidelines and Methods for Inspection of Existing Atmospheric and Low-Pressure Storage Tank.

- ST 307 – An Engineering Assessment of Acoustic Methods of Leak detection in Aboveground Storage tanks.

- ST 322 – An Engineering Evaluation of Acoustic Methods of Leak Detection in Aboveground storage Tank.

- ST 325 – An evaluation of a Methodology for the detection of Leaks in Aboveground Storage Tank.

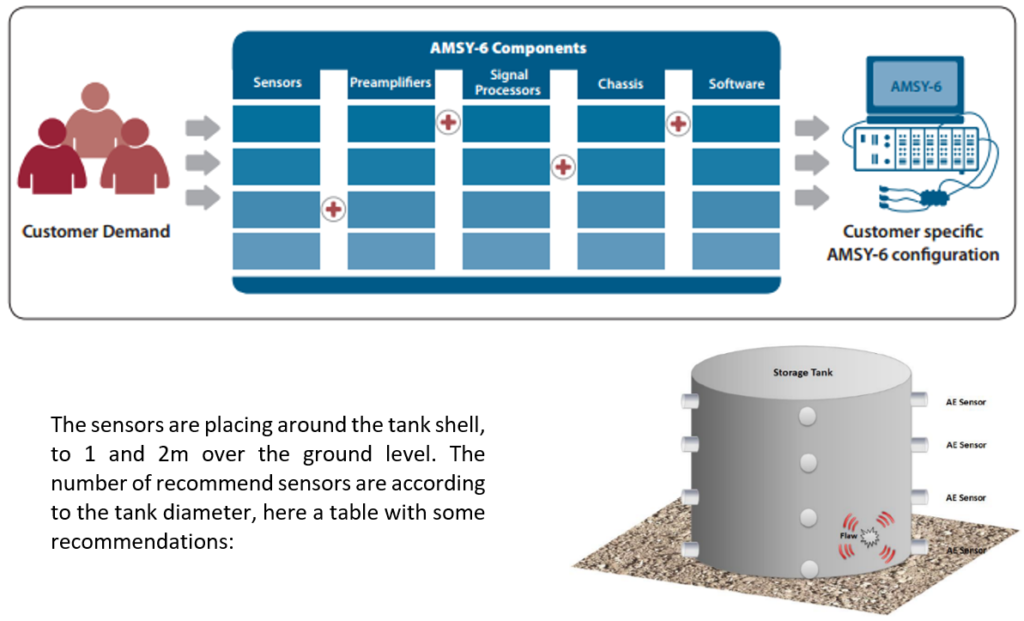

Typical installation of an AE system for monitoring AST’s

A typical layout of an AE system is compound as follow: Sensors, Pre-amplifiers, Signal processors, Chassis or Console, and Software. Normally, the AE systems are modular, and its size depend how big is the asset to inspect.

| Tank size (Diameter in m) | No of sensors |

| Under 25 m | 6 |

| From 25 to 30 m | 9 |

| From 30 to 50 m | 12 |

| From 50 to 62,5 m | 16 |

| From 62,5 to 75 mm | 18 |

| From 75 to 87,5 m | 21 |

| From 87,5 to 100 m | 24 |

Objectives of inspection

- Define in “paper” the probability of failure estimate based on tank AE test results.

- May also consider for leak detection.

- The results of the EA applied to a farm tank, can determine the severity of the condition of one tank over another, which allows generating a prioritization list for the output of a tank to maintenance.

Capabilities, Limitations, and References

- AE monitors tank floor “activity” to help identify localized corrosion areas and relative activity of floor (compared to other tanks).

- The assets can be operating (In fact a full container tank is needed to develop the test)

- AE does not provide direct floor thickness measurement or corrosion rate.

- The test usually is developed in the nights (A quiet atmosphere is ideally require)

Cautions and other application considerations.

- Background noise (e.g., Leaking valves, rain, wind, etc)

- Qualified operators

- Climate/active corrosion

Application and techniques

- Generally, requires the tank to be isolated (valves or blinding) for 24 hours and monitored with AE transducers.

- Techniques and interpretation of results may vary among vendors.

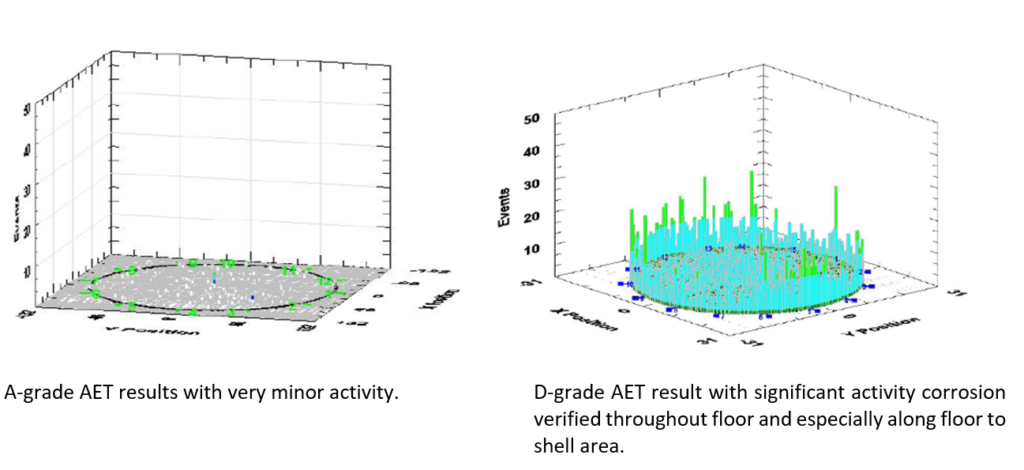

- One techniques approach with an AE grading system as follow:

A- Very minor / No Damage

B- Minor Damage

C- Intermediate Damage

D- Active Damage

E- Highly Active Damage

Acoustic Emission Example Results

In a tank farm, where the problem is to determine when and which tanks are taken out of operation, for the respective maintenance of the same, the AE plays a vital role! The results issued by the test, such as the corrosion activity graphs shown above, allow operators to build maintenance priority lists based on the severity presented in the activity graphs. The operational difficulty of removing a storage tank for maintenance is well known, hence the importance of this AE tests applied to tanks in operation.